Syringe Pump

APPL 310 – BME Design & Manufacturing II

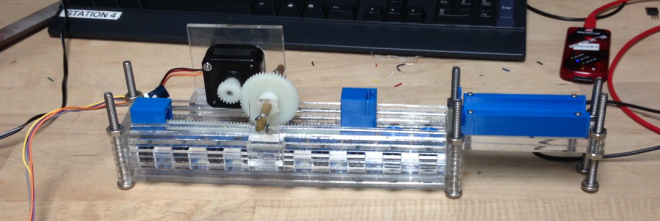

For our junior design course, we designed, manufactured, and constructed syringe pump. The device controlled volume and rate of fluid administered by syringe using rotations of stepper motor. Several SolidWorks models were developed throughout the design process. Modification were implemented following feedback from design review presentations. The pump includes an acrylic base, along with a stepper motor fixed in place by a backplate. The syringe holder and base rollers were designed in SolidWorks and printed in ABS plastic on a Fusion Deposition Modeling (FDM) machine. All gears were ordered from McMaster-Carr. Operated device using PIC micro-controller programmed in C.Completed project under $100 budget with three-student team.

Goals of the Project

- To design and assemble a syringe pump which will accurately distribute a precise amount of fluid

- To include a stepper motor, a gear system, and parts manufactured withan FDM and a laser cutter

Important Design Features

- Precision and accuracy

- Manufacturing Simplicity

- Cost efficiency

- Material Accessibility

- Durability

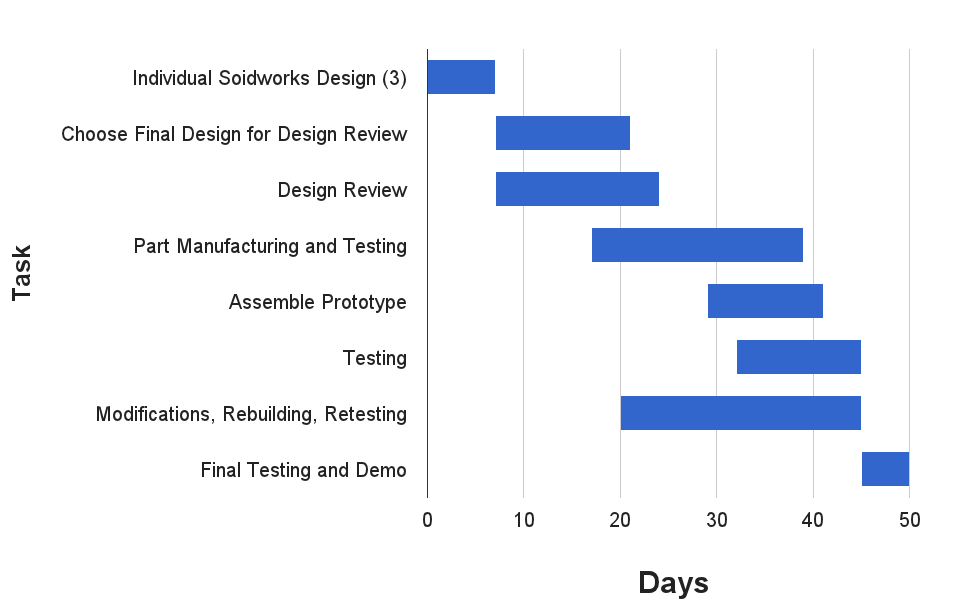

Production Timeline

Start Date: 28 February 2013

End Date: 20 April 2013

Preliminary Design Concept.

Each team member proposed a drive system and mounting configuration for the syringe.

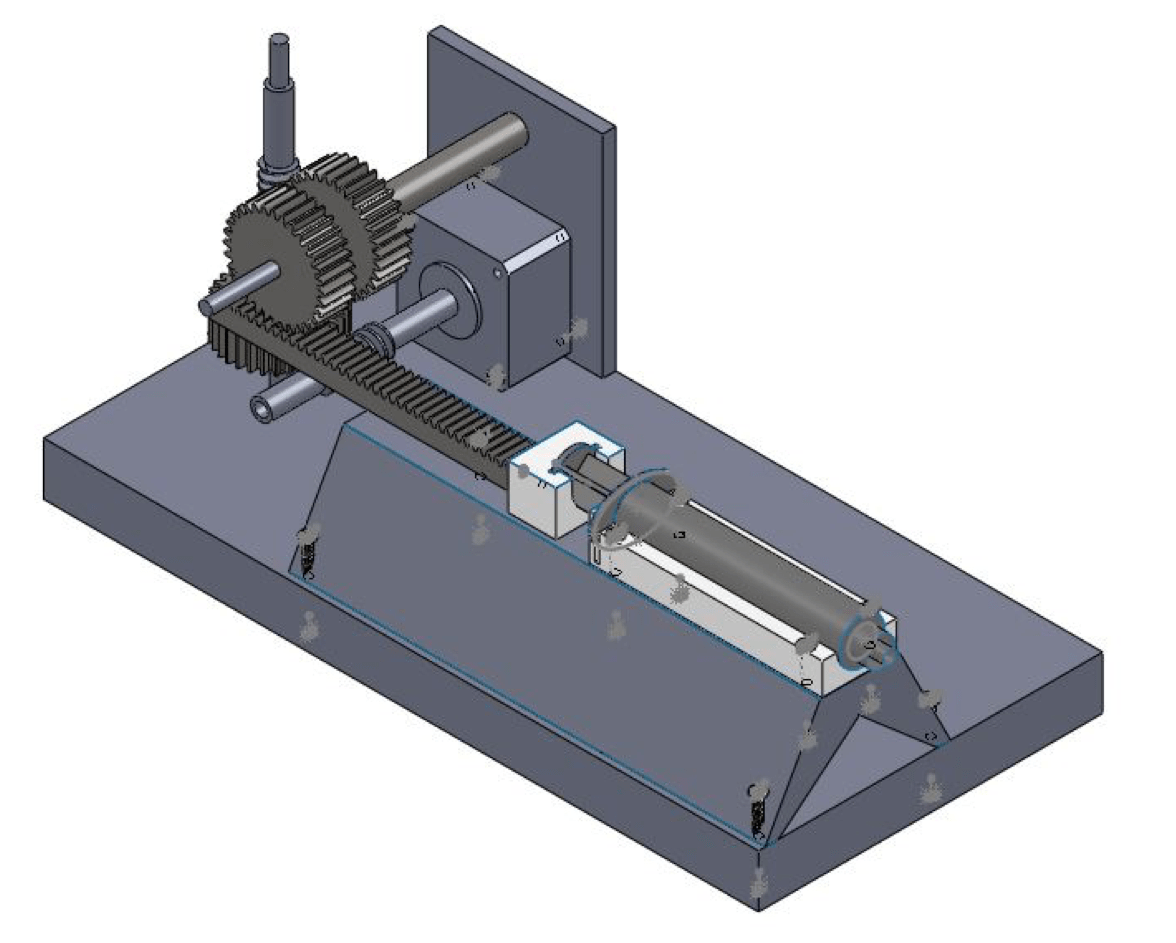

My initial design concept

Initial SolidWorks Design

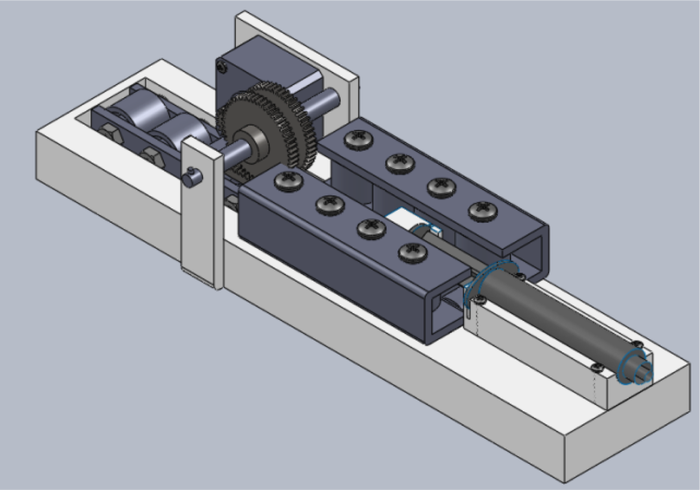

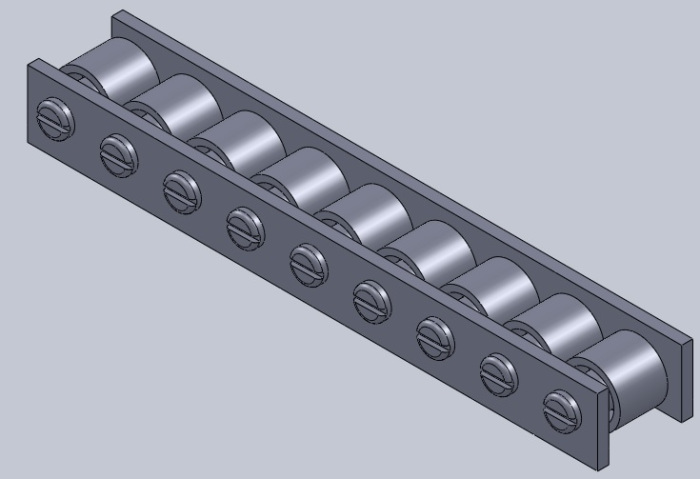

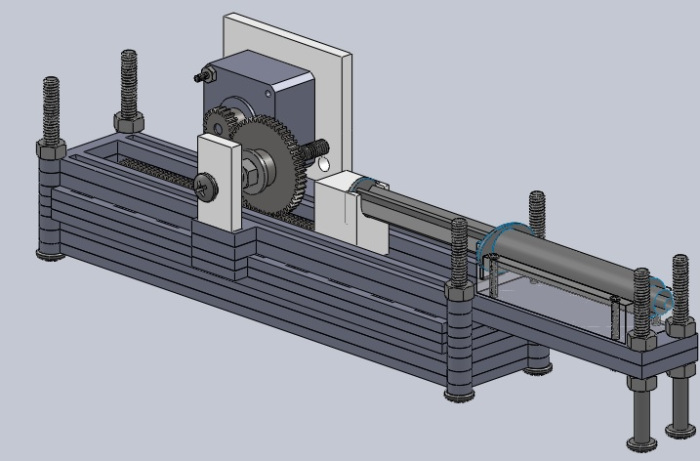

Our group decided to modify my initial SolidWorks design to present at our Design Review. Improvements to the model include removing excess material, adding guard rails to side of syringe-plunger guide, introducing rollers to ease movement, and re-designing the gear system. These improvements streamlined the system, made the device more durable, and allowed a greater gear ratio.

|

|

| Updated SolidWorks Design | Roller Insert for Base. Guard rails made out of acrylic. Rollers made on FDM (ABS). Plastic screws. |

Final SolidWorks Design

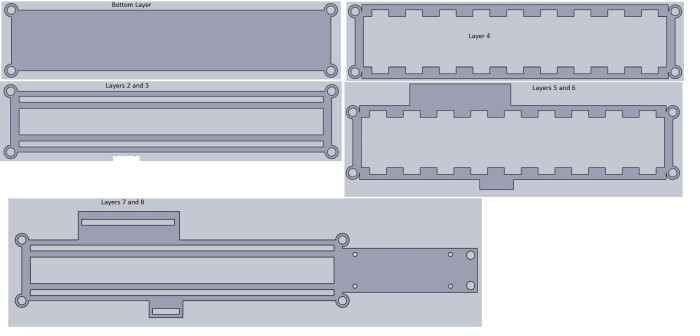

Our final SolidWorks design removed the guard rails due to concerns about excessive cost outweighing benefit. Additionally, the base was split into several acrylic layers for prototyping purposes. This allowed us to cheaply manufacture a prototype which could be easily assembled. The base layers, which may be seen below, included inserts for the gear and stepper motor attachments. These vertical layers were super glued once they were properly inserted to ensure they remained upright. The syringe holder was also modified to allow the insertion of several syringe sizes.

|

|

| Final SolidWorks Design | Base Layers |

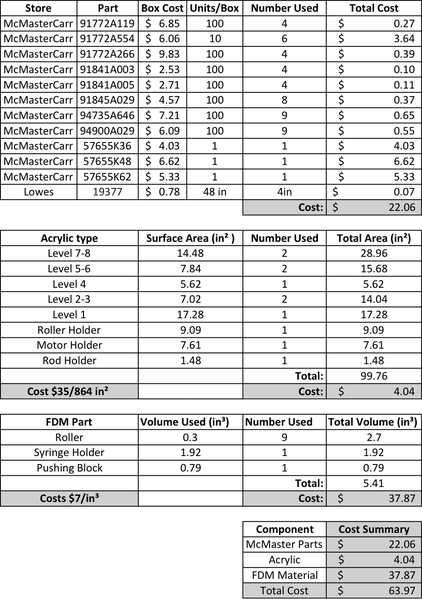

Cost Calculations

Future Improvements

- Stronger motor

- Larger gear ratio

- Adjustable gear and motor mounts

- Simpler base plate

- Possibly change to lead screw method to increase mechanical advantage